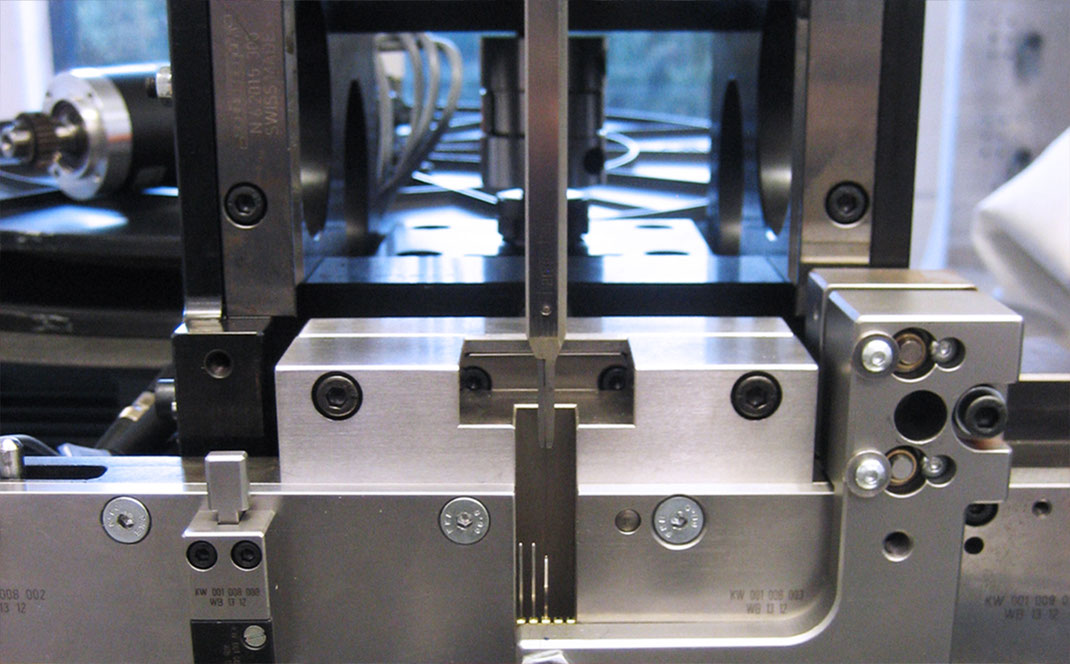

Automation technology – placement technology

Project planning, development and design of systems for placement technology:

- Fully or semi-automated implementation

- Component provision on a reel or in bulk

- Inline monitoring of the placement process (e.g. force-displacement or optical)

- Inspection of finished parts, e.g. using a vision control system or 3D scan

- Presence monitoring, electrical testing or HV inspection

- Labelling, e.g. with laser, to ensure subsequent traceability

- Output of finished parts in tray or tape-and-reel packaging possible